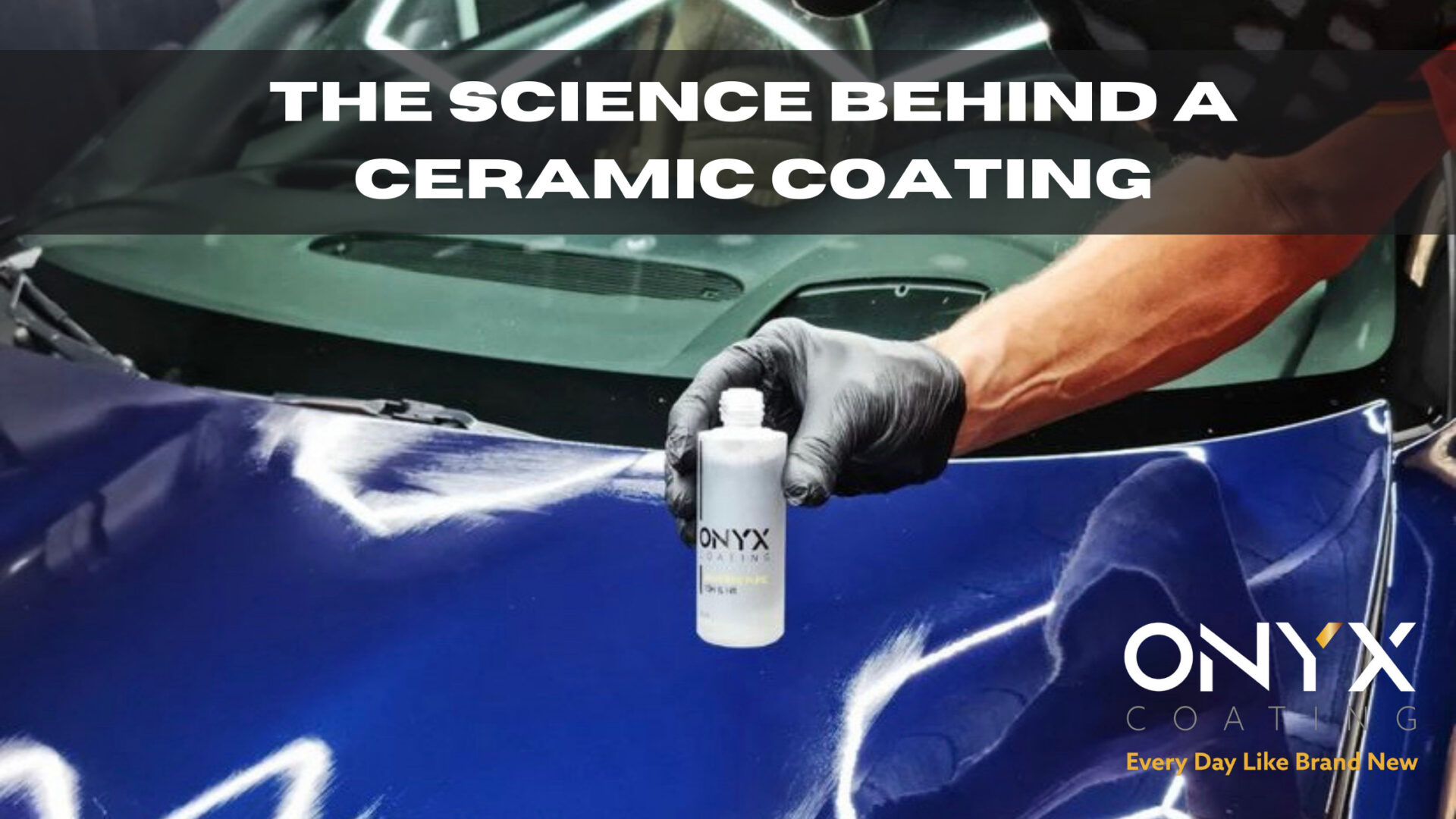

Everything you need to know about the science behind a ceramic coating! A ceramic coating is a type of protective coating applied to an object’s surface. The coating is made up of a variety of chemical components, which work together to provide several benefits. The rest of this blog post examines the science behind ceramic coating, describing how the various pieces work together to produce a highly durable and efficient product.

Ceramic coating refers to a thin layer of inorganic material applied to a surface, typically to the outer walls of a pot. The word “ceramic” comes from the ancient Greek word for pottery because most of the things to which ceramic coatings are applied are typically ceramic. Ceramic coatings are usually used to improve the object’s appearance or protect it from wear and tear.

There are two main types of ceramic coatings: those applied as a liquid and those used as a powder. Liquid ceramic coatings are typically made from a mixture of silica and water, which is then sprayed onto the object’s surface. On the other hand, powder coatings are made from a mix of silica and metal oxides fused using heat.

Ceramic coatings can be used on various materials, including metals, plastics, glass, and wood. However, they are most commonly used on automotive paintwork, as they provide a high level of protection against scratches, UV light, and other forms of damage.

A ceramic coating is a thin layer of inorganic material applied to a substrate. The substrate can be any number of things but is typically a metal or hard surface. Ceramic coatings are usually applied as a liquid and then cured, or baked, to form a hard, durable coating.

There are many different ceramic coatings, each with its own unique formulation. However, all ceramic coatings contain some combination of the following chemical components:

Silica: Silica is the primary ingredient in most ceramic coatings. It is a highly durable material that provides excellent wear and scratch resistance.

Titanium dioxide: Titanium dioxide is another common ingredient in ceramic coatings. It provides UV protection and helps to keep the coating from yellowing over time.

Zirconium oxide: Zirconium oxide is often used with titanium dioxide to provide even better UV protection. It also helps to increase the hardness of the coating.

Alumina: Alumina is another common ingredient in ceramic coatings. It provides excellent abrasion resistance and helps to improve the overall durability of the coating.

The primary purpose of a ceramic coating is to provide a durable barrier between the substrate and the environment. The chemical elements in a ceramic coating work together to provide this protection.

Silica is an essential ingredient in a ceramic coating. It makes up most of the coating and provides the most protection. Titanium dioxide and zirconium oxide are also necessary ingredients. They help protect the substrate from UV radiation and wear. Alumina is another vital ingredient that helps to increase the hardness of the coating.

A ceramic coating is typically applied as a liquid and then cured, or baked, to form a hard, durable coating. The curing process causes the chemical elements in the coating to crosslink and bond together, creating a solid barrier.

As mentioned before, the main component of a ceramic coating is silica. Silica is a hard, durable material that is resistant to scratches and wear. It also has a high melting point, meaning it can withstand high temperatures without breaking down. Titanium dioxide is another vital component. It helps to reflect UV radiation, keeping the substrate from being damaged by the sun. Zirconium oxide and alumina are also essential ingredients. They help to increase the hardness of the coating, making it more resistant to damage.

The hardness of a ceramic coating is necessary because it determines how well the coating will resist scratches and other damage. The more complex the coating, the more resistant it is to damage. There are two ways to measure the hardness of a ceramic coating: the Rockwell scale and the Vickers hardness test.

The Rockwell scale measures indentation hardness, which measures how well a material can resist scratches or dents. The higher the number on the Rockwell scale, the more complex the material. The Vickers hardness test measures scratch resistance, which measures how well a material can resist scratches. The higher the number on the Vickers hardness test, the more resistant the material is to scratches.

Ceramic coatings typically have a hardness of 7-8 on the Rockwell scale and a hardness of 3000-4000 on the Vickers hardness test. That means they resist scratches and are less prone to wear than others.

Putting a ceramic coating on your car provides extra protection for your paint job and makes the paint a bit easier to clean. If you’re looking for a relatively easy way to keep your vehicle looking its best, then a ceramic coating is worth considering. Learn more about our products on our website. Thanks for reading, and feel free to share this article with your friends if you found it helpful!

Watch as water beads off the deck with our super hydrophobic coatings.

Protect the paintwork from UV damage and keep its vibrant colour despite the conditions.

Let the fear of a rough docking be a thing of the past with a 10H coating.

With minimal maintenance, our products are guaranteed to provide protection for years to come.

With our chemical and contaminant resistant coating, the surface is kept clean. Needing only minor occasional maintenance.

Trusted in 70+ countries, Onyx Coating is the top choice for professionals and car owners seeking premium protection.

Our ceramic coatings adhere to the surface making it resistant to corrosion and oxidation and contamination-free.

Bonds tight with the surtace to maintain a uniform cover and protect the surface evenly.

If you are interested in our products or keen to work with us, send us a message and we will get in contact with you to schedule a quick call or contact us via our email info@onyxcoating.com

Once this information has been received our team will review the accounts and get into contact with you.

With the world’s first N1 nano coating product under our name, we are one of the most advanced automotive protection providers in the market.

Sign up for the latest offers & promotions

© ONYX COATING 2025. All Rights Reserved.