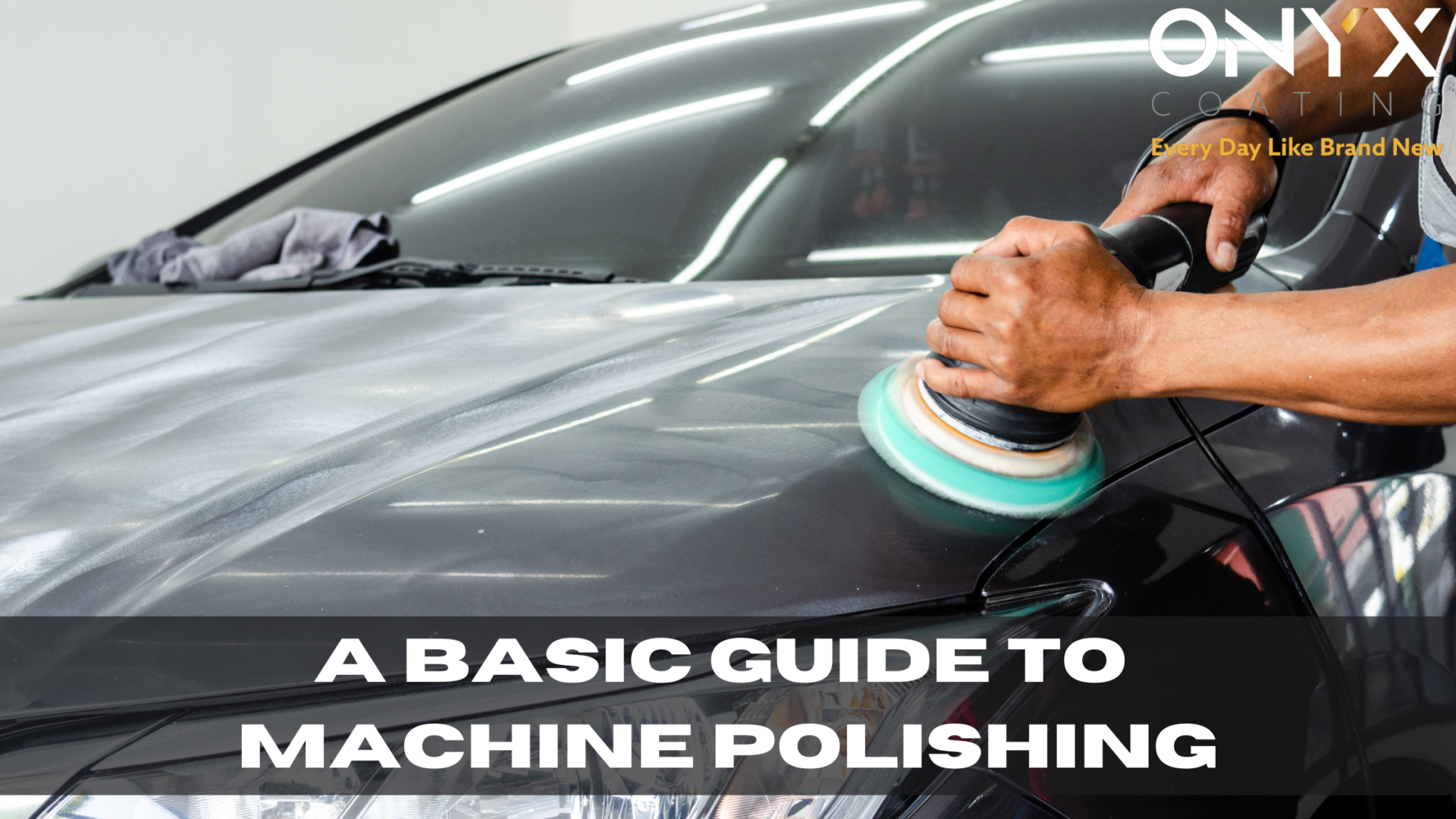

Polishing is an essential part of the detailing process which is why we created a guide that’ll give you everything you’ll need to know about what polishing is, how it’s done and what to do and not to do. When it comes to polishing there are many tips and tricks to finesse the technique as well as the range of products that are used, which is exactly why in this guide we will outline all the details about the process.

Polishing is defined as various things such as cutting, refining, resorting, compounding, and various other names, or better said polishing “categories”. It is simply the mechanical action, fulfilled by hand or using machines, of removing defects on the paintwork through surface abrasion. The process involves “wearing” or abrading the top layer to remove a microscopic amount that contains these said defects. This in turn creates a smooth layer and also results in light bouncing off in a more uniform direction (vs. having swirl marks), leveling out the surface and making it appear not only shiner but also deeper.

One thing to keep in mind is the differences or subcategories of polishing.

This refers to how coarse the cutting compound/ product is that is used to remove said defects.

Finer finishing compounds, and or products will have a less aggressive level of cut, therefore they are designed to smooth out the surfaces.

Meanwhile, on the contrary, the coarse cutting compounds will be more abrasive and it will remove the defects and paintwork at a faster pace.

This leads to the question, how intense does one need to polish? How much of the surface layer should be removed and with what products?

It really does depend on the vehicle, the type of vehicle and when it was manufactured as each has different types of paintwork and therefore needs to be polished according to this.

This refers to classic and vintage cars and means that the type of paintwork is statistically the color pigment layer which is the base coat applied to the panel over the first layer. This means that there is no protective clear coat on the paintwork.

What does this mean for polishing?

This means that when you use a machine to polish single-stage paintwork you are actually removing the top layer of the color coat.

Every vehicle manufactured after the mid-1980s will most likely use two-stage paintwork, meaning that the paint is applied in two stages. These stages include the color base coat which is followed up by a protective clear coat (lacquer). This type of coating means that there are metallic and pearlescent paints that contain aluminum powder or ceramic crystals that are simply mixed in with the base coat. This type of extra layer gives a deeper level of gloss and reflection.

What does this mean for polishing?

This lets us know that when we polish, we aren’t polishing the color pigment itself but rather the clear coat. After the process of polishing what we are left with is a clear view of the defect.

How far you should polish all depends on the thickness of the paint, which varies according to the manufacturer.

Measuring the thickness of paint

The thickness is measured in microns. Single-stage paintwork has a thinner layer while two-stage paintwork contains three levels of thickness: the first being the primer layer (12-40 microns), the second being the base coat (25-40 microns), and the clear coat (45-70 microns).

This is where paint depth gauges come into play. When it comes to removing any paint defect, one must level out the paint until one gets to the paint defect. Most vehicles will have plenty of clear coats meaning that it’s best to leave all of this to an experienced detailer who knows what they are doing and how best to remove the defects.

That’s everything you need for a guide to machine polishing. Stay tuned for the next blog article in which we will dig into the common defects of polishing!

For other FAQ’s about ceramic coatings, paint defects, and detailing products check out our FAQs!

Al-Rabiya Auto Accessories is the Official ONYX COATING Distributor In the MENA Region. As a key player in the region, Al-Rabiya is pivotal in introducing leading U.S. and German brands to the MENA market, ensuring their availability to car care professionals and vehicle owners. The GCC’s harsh climate and demanding terrain require high-quality, durable paint protection solutions. Al-Rabiya has proactively identified this need and guarantees a steady supply of top-tier products manufactured in technologically advanced countries like Germany.

Watch as water beads off the deck with our super hydrophobic coatings.

Protect the paintwork from UV damage and keep its vibrant colour despite the conditions.

Let the fear of a rough docking be a thing of the past with a 10H coating.

With minimal maintenance, our products are guaranteed to provide protection for years to come.

With our chemical and contaminant resistant coating, the surface is kept clean. Needing only minor occasional maintenance.

Trusted in 70+ countries, Onyx Coating is the top choice for professionals and car owners seeking premium protection.

Our ceramic coatings adhere to the surface making it resistant to corrosion and oxidation and contamination-free.

Bonds tight with the surtace to maintain a uniform cover and protect the surface evenly.

If you are interested in our products or keen to work with us, send us a message and we will get in contact with you to schedule a quick call or contact us via our email [email protected]

Once this information has been received our team will review the accounts and get into contact with you.

With the world’s first N1 nano coating product under our name, we are one of the most advanced automotive protection providers in the market.

Sign up for the latest offers & promotions

© ONYX COATING 2025. All Rights Reserved.